When it comes to securing large packages, strapping is often the most effective solution.

We’ve given you a guide to strapping machines before which covers the differences in the machines, but how much do you know about strapping itself? This guide will help you understand the different types of strapping, what each type of strapping is used for and

What is Strapping?

Strapping bands are the strong ‘ribbons’ that you often see around boxes or pallets. They keep goods tightly in the package and make sure they don’t get separated or damaged in transit. Its origins date back to the late 19th and early 20th centuries, when industries sought stronger and more efficient ways to secure goods for transport. Before strapping, ropes and metal wires were commonly used to bundle and stabilize shipments, but these methods were often unreliable and prone to breaking under heavy loads. By the mid-20th century, advancements in materials led to the development of polypropylene (PP) and polyester (PET) strapping. These plastic strapping materials gained popularity in industries ranging from logistics to agriculture. Today, strapping continues to evolve with high-strength composites and automated strapping machines, improving efficiency and sustainability in global trade and transportation.

What types of strapping are there?

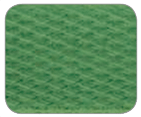

This is dictated by what material the strapping is made of. In our range there are 5 types of strapping. These are paper, polypropylene (PP), corded/textile, polyester and steel. Each type has its own advantages and best use-cases depending on its properties. For example, polypropylene strapping has the lowest cost and is one of the most popular variants in the packaging world. It is made of a type of plastic with a relief structure for more grip. The strongest type is steel strapping: ideal for the construction sector, for example.

In the table below you can see how the different types of strapping compare:

| Material | Applications | Properties |

Paper | • For very light goods. • For short-term use (indoors only). • For manual or machine strapping. | • Tensile strength up to 55 kg . • Environmentally friendly: 100% renewable raw materials. |

Polypropylene | • For light goods. • For short-term use (indoors only). • For manual or machine strapping. | • Tensile strength up to 300 kg . • With embossed surface. • Most elastic. |

Polyester | • For heavy goods. • For long-term use (indoor/outdoor). • For manual or machine strapping. | • Tensile strength up to 1070kg . • With embossed surface. • Resists sharp edges. |

Textile | • For very heavy or fragile goods. • For long-term use (indoor/outdoor). • For manual strapping. | • Tensile strength up to 1200 kg . • With soft surface. • Resists sharp edges. |

Steel | • For very heavy goods. • For long-term use (indoor/outdoor). • For manual strapping. | • Tensile strength up to 725 kg . • Resists sharp edges. • Least elastic. |

Here are a few common FAQs about strapping

Why is it best to limit PP strapping to short term use?

PP band is much more elastic than the other types. After stretching, the band will want to revert to its original length. However, it also has the tendency to ‘relax’ after a while (to remain stretched). It then loses some of its elasticity (± 35% after 2 weeks). This makes it less effective in the long term.

Why is it best to use PP strap only indoors?

PP strap is less resistant to UV light. This light is detrimental to the quality and colour. White straps in particular suffer from this.

What are the different kinds of strapping used for?

All strapping serves the same approximate purpose: it’s used to band together products or to hold a package securely shut. By using strapping, you can facilitate transport and make it safer to move products on pallets. Which strapping you should use will depend upon what it is you’re attempting to strap up.

As a rough steer, here is what each type of strapping is best used for:

- Paper strapping: can be used for applications that previously required plastic wrapping film, such as for strapping packages, bundling and grouping products, etc. The paper strap is also an environmentally friendly alternative to PP strap with limited tensile strength.

- Polypropylene strapping: bundling newspapers or magazines, additional protection against theft for light packaging, closing cardboard boxes or crates, reinforcing (light) pallet loads, etc.

- Polyester strapping: for palletizing medium to heavy loads, grouping pipes, etc.

- Textile strapping: strapping of goods with a fragile surface (such as wood) and objects with protruding or pointed corners (such as planks and tiles), etc.

- Steel strapping: suitable for securely strapping very heavy, sharp and round loads such as building materials.

How to use a manual strapping tool

You’ll need more than the strapping itself to get to work on those packages. Once it’s applied, how do you tighten your band and what do you use to secure the ends? Well, that requires some additional tools. First, let’s talk about how to strap products manually. Using a manual strapping tool has got the lowest cost of goods associated but will be more intense on manpower and time. You will need to use one of these basic tools: buckles or seals but Remember! A buckle is only suitable for a strap made of PP (polypropylene) or textile, while a seal can be used for a strap made of PP, polyester or steel.

Buckle

|

|

Seal

|

|

Did you know… you can also strap manually using a paper strapping band?

How to use a strapping machine

For strapping in larger quantities, you will be best served by using a strapping machine. When it straps a package, the ends of the strapping band are welded together which undoubtedly provides you with the strongest closure and with minimal manpower needed. When you strap by machine, it is best to use a plastic strap with a relief structure (PP or polyester). The side with the deepest relief should always be placed upwards in the machine. This allows the strap to melt and adhere better. The two main types of strapping machine are either the large singular units or handheld models.

Hand strapping machines | These devices have the highest working capacity and can be used vertically and horizontally. Good to know: strapping devices also work ‘in the air’. The device does not necessarily have to rest on a flat surface.Check out the GT Smart for an example. |

Strapping machine | Ideal for strapping loose packages and boxes. All you have to do is hang the strapping band around the package. The sealing and cutting of the band are done automatically. |

Want to see an example of the GTSMART in motion? Check out our video below!

Did you know… we have a guide to Strapping Machines that can help you decide which machine is the best fit for you, complete with a comparative spec product guide.

Which accessories are useful for strapping?

While all you need to strap a package is the roll of strapping and the tool to seal it, there are a few accessories that help improve usability significantly.

Corner profiles and corner protectors are essential for protecting goods when strapping pallets. Corner profiles help distribute the tension created by the strapping band, preventing it from cutting into the products while also adding stability to the pallet load. They also ensure that the strapping bands stay in place more securely. On the other hand, corner protectors are used only at specific corner points where the strapping band might cause damage, making them ideal for securing smaller packages.

In addition to protective accessories, specialized tools improve the efficiency and safety of strapping. Steel strapping shears are designed to hold the strapping securely while cutting, reducing the risk of it snapping back and causing injuries. A strapping dispenser makes handling strapping rolls much easier by allowing users to move and unroll them efficiently. Many dispensers also feature a built-in container for storing additional tools, making the strapping process more organized and convenient.

At RAJA, we’re always striving to improve our service and our product offering. If you have any additional questions about how to strap your products or pallets, get in touch or leave a comment down below. We’re here to help you exceed your goals!