Single, double and triple wall cardboard boxes are all designed to fit different purposes and for use in different circumstances. Triple wall is the strongest and most heavy duty of the three options, so what is it that makes the triple wall box so strong, and what are triple walled boxes best used for?

The science behind triple wall corrugated cardboard boxes

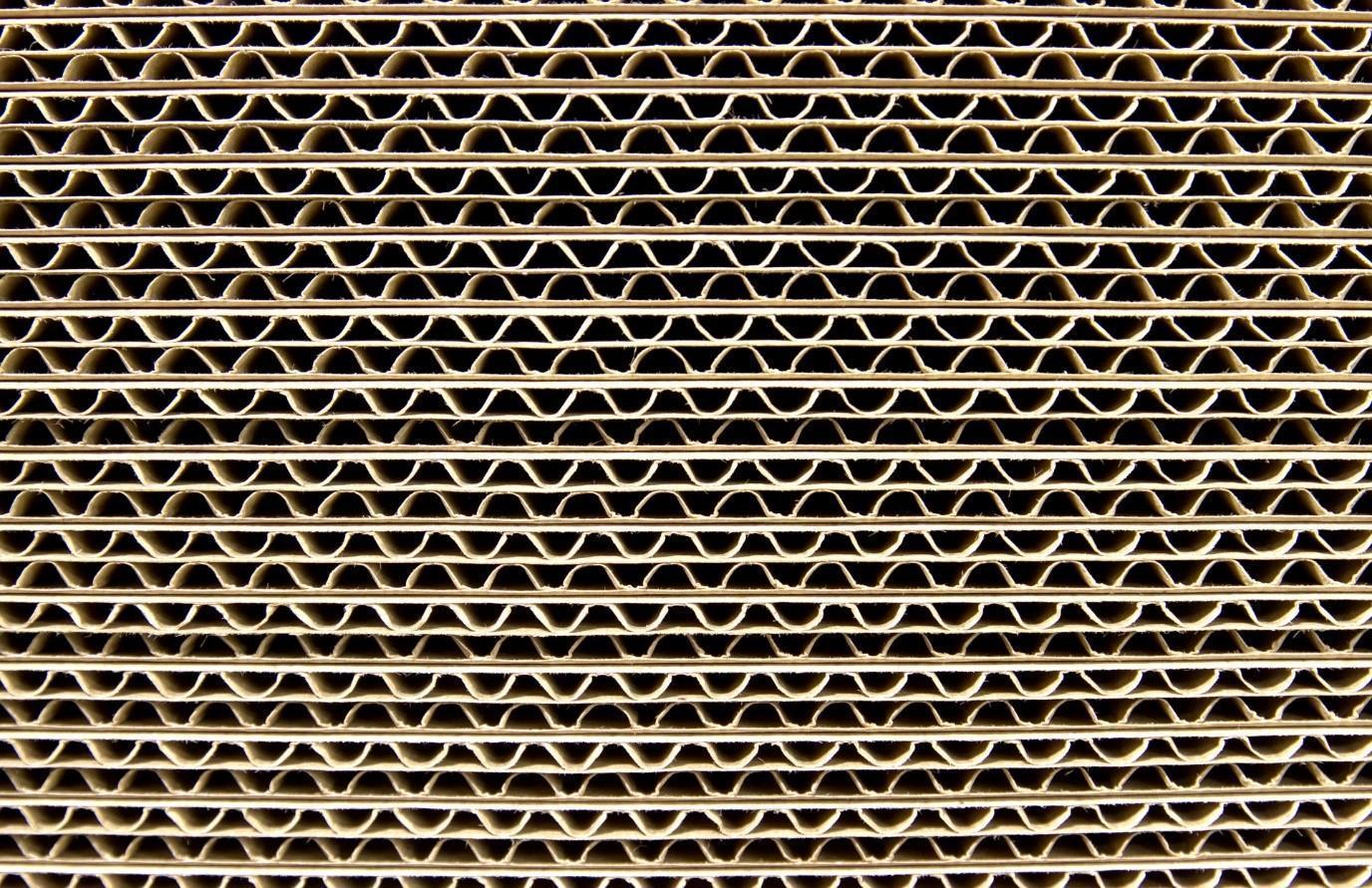

The strength of any corrugated box lies within its material and its construction. Standard fibreboard corrugations have two components: the liner board and the medium. The liner board encloses the connected mediums of arched material, all cemented with strong adhesive – the sandwich like construction is where the strength of corrugation lies.

There are 5 types of standard box wall construction: these range from A-flute to F-flute – examples of the formation of A, B flute cardboard and C flute corrugated cardboard can be found below:

A-flute is the thickest gauge of corrugated card, followed by C and then B to F in alphabetical order. C flute corrugated cardboard is the most commonly found size due to it being a happy medium between A and B-flutes. As a compromise it offers good strength but without compromising ease of use or storage.

When making multi walled boxes it is common for a combination of different flutes to be used as each category has different characteristics which can help to strengthen a box. A frequently used combination in corrugated boxes is BC flute corrugated, which consists of one B flute corrugated and one C flute corrugated – it’s usually regarded as a strong box-type and can hold very large items safely.

When dealing with heavy items, double wall cardboard boxes are not always sufficient; even though still practical for most heavy goods. This is where the triple walled box comes into play. Ideal for the storage and transport of heavy or delicate items, such as machine parts or large glassware. Triple walled boxes offer strength and protection when it is vital.

The triple flute layers of corrugated medium flutes and quality linerboard allows the packaging to resist bending and pressure from all directions. Even placed vertically on its ends, the box is capable of supporting considerable amounts of weight on its corrugated frame. The construction of these boxes is so efficient that they end up with durability comparable to that of wooden boxes. For double wall boxes, there is a double layer of corrugated flute – offering a lot of strength and support but not as much as triple wall boxes. And for single wall cardboard boxes, there is one layer of corrugated flute – offering a basic level of support for lighter items.

Its protective properties make triple wall boxes ideal for heavy applications, large shipments and delicate items.

The corrugated cardboard properties of triple wall

- The corrugated carton box specification makes it strong, meaning its strength is Ideal for heavy duty items such as metal parts, compressors, boilers, pumps, industrial tools and machinery.

- Although the box is light it can carry heavy weight, this is ideal for logistic transport where the package is charged according to weight.

- It brings an incentive to business: reducing transport costs whilst ensuring quality is enticing property for any logical budget. Timber is much more expensive to import in countries such as Australia and Indonesia.

- Compared to its timber counterparts, the corrugated cardboard properties of the triple wall design will absorb any potentially damaging collision, abrasions and temperature changes, whereas timber is prone to splinter and conduct the energy to its contents, reducing health and safety concerns.

- Because of its heavy duty nature you have the possibility of re-use, which could cut the overall packaging spend and reduces carbon footprint.

- 100% recyclable and totally reusable.

The corrugated cardboard properties of triple wall boxes allow it to be used for the more precious or the more hefty cargo, built for the jobs that other boxes might not be able to handle. Their high price tag means that many suppliers don’t offer the triple flute layered box, and the storage space required to house the boxes means that some distributors are unable to keep them in stock.

Corrugated packaging definition:

Corrugated boxes 101

Expert insight

To get an insider’s view of the triple-walled box, we had a chat with RAJA’s Product and Purchasing Director, Chris Liddell:

Q: What in your opinion is the main advantage of triple-wall packaging?

A: Strength mainly (impact/burst/compression/edge). Able to take a lot of weight and therefore a worthy alternative and has cost advantages vs. the more traditional wooden boxes.

Q: What products or delivery methods require triple-wall?

A: Generally heavy products that require good strength from the box to handle/carry its weight. E.g Car part and heavy machinery.

Q: What are the dangers of not using triple-wall packaging for the above products/deliveries?

A: If the box used is under spec, we could see the box “falling apart” and subsequently its contents dropped/damaged.

We’re one of the leading suppliers of triple wall packaging in the UK and we offer the largest range available at competitive prices.