Imagine a technology that could totally revolutionise packaging and the delivery of goods. That could protect and enclose and which could also feature branding and other information? Well, paper bags did just that when they emerged in the mid-late 1800s in the US.

But how are paper bags made, what are paper bags made from and what can paper bags be used for? In our guide, we take a look at the ingenuity and simplicity behind these useful everyday packing staples. And show you how they can be used for everything from storing your bits and bobs, to giving gifts the wow factor.

Who invented the paper bag?

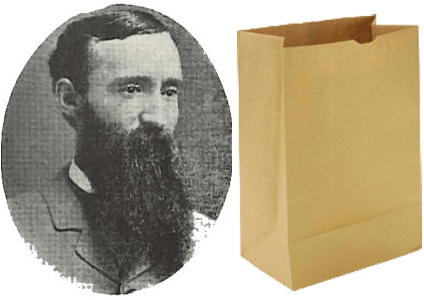

While the inventor of the paper bag is lost to obscurity, the invention of the bag’s square bottomed design is widely accredited to one Luther Childs Crowell of Wellfleet in Massachusetts.

When was the paper bag invented? While Crowell’s flat-bottomed bag appeared in the 1870s, one Francis Wolle, a US schoolteacher, invented the first machine to mass-produce these bags as early as the 1850s. Wolle and his brother patented the machine and founded the Union Paper Bag Company, which leads us nicely to how paper bags are made.

How are paper bags manufactured?

Paper bags are manufactured from paper pulp, which is pressed into flat sheets or rolls of paper. These rolls of paper are cut to size, that means twice the required height of the finished bag. These cut sheets are then folded over and the two parallel open sides glued together. This can either be by pressing the glues sides together or heating and pressing.

This makes a simple flat bag made from paper.

To make a more complex flat-bottom design, a similar process is followed. Only, there are more complex folds at the bottom of the bag so that the finished bag is square or oblong with an open top.

For bags with handles, separate paper handles are then fixed using adhesive glue.

What are paper bags made out of

What are paper bags made of would, on the face of it, seem to be a silly question: paper. But there are many designs and styles, all made from different kinds of paper depending on what the bag is going to be used for.

Standard brown bags are made from Kraft paper, but it can be made from all kinds of paper and in any colour.

Kraft bags can also be made from laminated paper. This has a plastic coating on the inside to protect the bag from moisture from the goods contained in it or to keep moisture out.

Bags made from Kraft paper can also be designed in any colour and any weight of Kraft paper. These are typically made from 60gsm paper and come in a huge range of sizes.

More sturdy Kraft paper gift bags are made from 90gsm paper and can be coloured, or brown – or retro polka dot style.

As with all things paper, it can also be made from recycled paper and recycled Kraft paper. This offers a good, sturdy and environmentally friendly way to package goods, gifts and more. Typically, these are made from strong 110gsm recycled Kraft paper.

Why use paper bags?

Paper bags can be used for so many things. Bags made from paper are a cheap, easy and are a sustainable way to store and deliver all manner of things – so long as they aren’t wet, or really heavy.

How to measure a paper bag is simple: measure its height, width and depth (gusset) – multiply these together and you will get its volume.

How much can a paper bag hold depends on its size. These handy bags come in all sorts of sizes from small ones measuring 200x300x100mm right up to ones as big as sacks measuring 450x800x290mm.

How much weight can a paper bag hold depends again on its size and on the strength of the paper used. Small bags made of 70gsm Kraft paper have a breaking strain of 4kg, while the largest paper sacks made of 90gsm paper can take ten times that, having a breaking strain of 40kg.

In between lie the myriad sizes of bags available, each able to take a weight of 40kg or less. To see the full range of available sizes and their relative strengths, take a look at this chart.

For additional advice on paper packaging, our Packaging Experts are here to help you find the right solutions and arrange next day delivery. Simply call us on 0800 542 44 28 or visit www.rajapack.co.uk.

Thanks for the useful informaiton about paper bag, you have done great work, Raja.

Thank you. The blog was very helpful.